Model |

Capacity |

Roast time |

Heating power |

Motor power |

Voltage |

Overall size(mm) |

Size of drum(mm) |

AE-12 |

4500Kg |

/ |

31KW |

/ |

360V-430V |

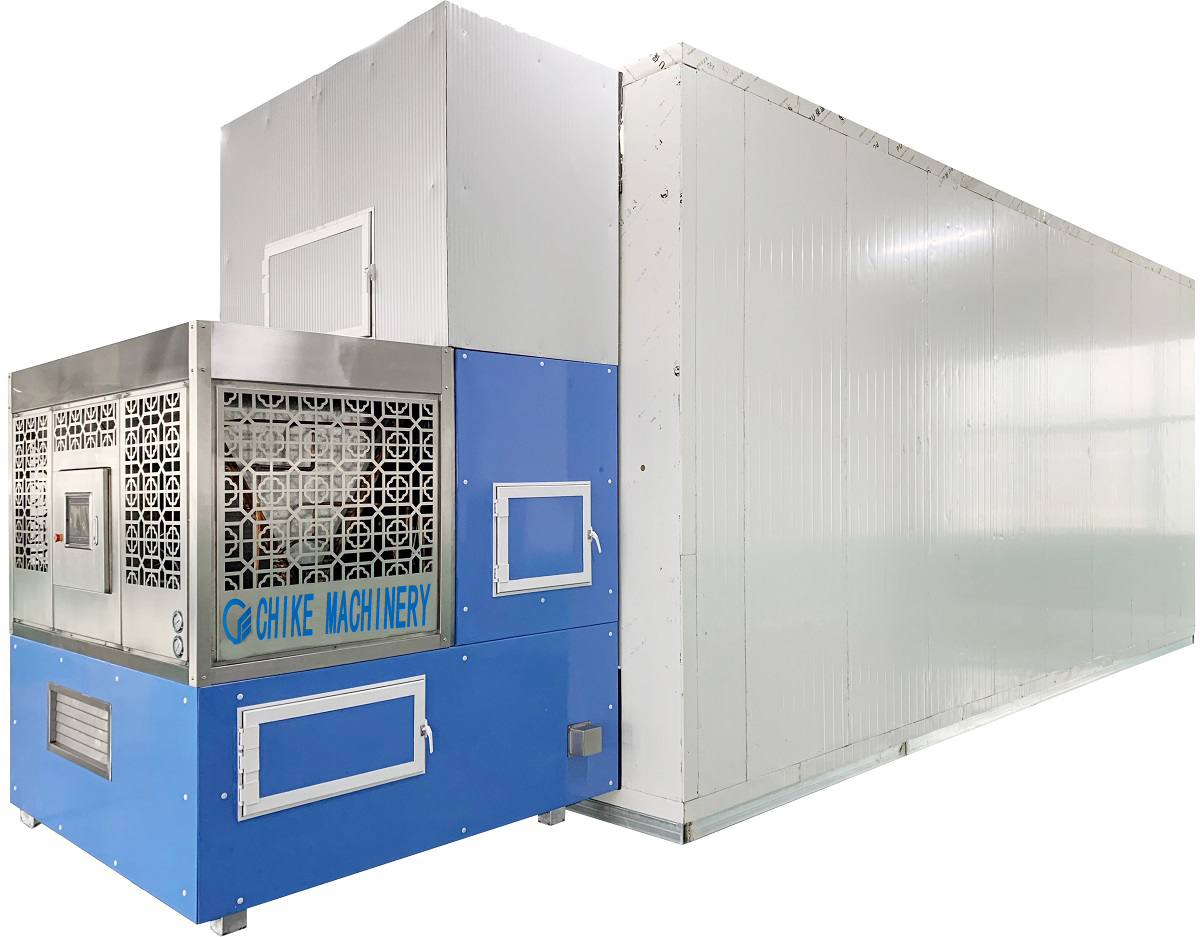

10210*2900*3500 |

/ |

1. Low power consumption: the device is of an integrated design, compact structure, low heat loss.

2. Fast temperature rise: Through actual use and the standard test of the empty flue-cured tobacco room, when the outdoor temperature is 10 ℃ -15 ℃, the heating time can reach 70 ℃ in 45-55 minutes. The outdoor temperature is 15 ℃ -20 ℃ When the heating time is 40-50 minutes, the baking room (empty baking room) can reach 70 ° C; when the outdoor temperature is 20 ° C-25 ° C, the heating time is 35-45 minutes (the empty baking room) can reach 70 ° C; outdoor temperature At 25 ℃ -30 ℃, the heating time is 30-35 minutes. The oven (empty baking room) can reach 70 ℃. When the outdoor temperature is 30 ℃ -35 ℃, the heating time is less than 30 minutes.

3. Reasonable design and beautiful appearance: the human-machine interface is designed with humanity, the control panel is designed on the front, and is equipped with an infrared recognition system.

4.High thermal efficiency: The equipment is an integrated flue-cured tobacco room design structure, built-in waste heat recovery system and internal circulation main air duct control valve, which reduces the heat energy loss during the dehumidification process, so that the heat energy is fully utilized.

5. Low failure and long life: Because the device is an integrated structure, installation, debugging and detection are relatively complete before leaving the factory. The installation, protection, standardization and reasonableness of each component greatly reduce the failure rate of the device.

6.Convenient disassembly: The device is an integrated mechanism. When replacing the use site, the construction technology requirements are low, which is convenient for disassembly.

| Model | Voltage | Power | Frequency |

| AE-12 | 360V-430V | 14KW | 50/60Hz |

| Capacity | Consumption | Acclimatizing temperature | Energy type |

| 4500Kg | 450-800kwh | 10-45℃ | Air source(AE) |

| Compressor power | Control method | Rated current | Heating capacity |

| 6hp*2 | PLC | 30A | 31000W |

| Waste heat recovery efficiency | Fan capacity | Noise | Emergency electric auxiliary heating |

| ≥30% | 1.1KW*2 | ≤85dB(A) | 20KW |

| Wind pressure | System mode | Circulation air volume | Control precision |

| 170-250pa | Two-way system coordination | 15000m³/H | Dry-bulb±1℃,wet-bulb±1℃ |

| Host size(mm) | Kang room size(mm) | ||

| 2010*1930*3595 | 8200*2900*3500 | ||

1.Price term: EXW,FOB,CIF,CNF,DDU

2.Materials: Main body 304# Stainless steel, the batch 430# Stainless steel.

3.Payment: TT,L/C,Paypal,Alipay,Wechat,Credit card.

4.Delivery time: supply in stock, production line need 20-30working days.

5.Working life: 8years.

6.Customized service: accept. MOQ: 5sets

7.Supply quantity: 100sets/month

8.Package: packing in ply wooden case.

9.Shipping term: by sea, by air and by train.

10.Warranty term: 2years.

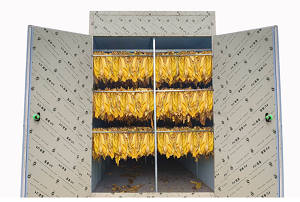

Special equipment for the initial curing of tobacco leaves

Copyright © 2016-2025 Xuchang Chike Machinery Manufacturing Co.,Ltd.